Stock in EU Full Automatic SMD 4 Heads 50 Feeders Pick and Place Machine SMT550 Led Light PCB Circuit Board Making SMT Machine

Stock in EU Full Automatic SMD 4 Heads 50 Feeders Pick and Place Machine SMT550 Led Light PCB Circuit Board Making SMT Machine

Couldn't load pickup availability

SPECIFICATIONS

Application: SMT Pick and Place Machine

Average mounting rate: 8,000 PCS/hour

Average power: 400 W

Brand Name: YXING

Buffering range of suction nozzle: 4.5 mm

Certification: CE

Complex speed to mount resistance and Chip: 6000/h

Compressed air: 0.6-0.7 Mpa

Dimension: 900*1140*900mm

Driving mode: Taiwan TBI ball screw

Gas quality requirements: oil-water separation device, dust filter device, air pressure stabilization device

Guide rail: Taiwan TBI Linear Guide rail

Maximum circuit board area: 400*200 mm

Maximum mounting rate: 9,500 PCS/hour

Maximum movement range of Z axis: 20 mm

Minimum air capacity of pump: 80-120 L/min, volume more than 60 L

Model Number: SMT550

Mounting accuracy range: 0201-40*40mm,Pin spacing 0.3mm Chip(Matching which support electric feeder can mount the 0402,0201)

Nozzle Vacuum Source: Japan CKD High Speed On-off Vacuum Generator with Vacuum Damage

Number of cameras: a Mark camera, four high-speed cameras, a high-definition camera

Number of mounting heads: 4

Origin: Mainland China

PCB access mode: automatic Left-in and right-out access, supporting left-right device connection function

Positioning accuracy: 0.01 mm

Power supply: 220V/110V, 50 Hz

Product weight: 210KG

Quantity of feeders: 50 PCS

Quantity of trays: Up to 48 non-feeder feeding components are supported, each of which can specify its coordinates within the mounting range

Recognition Mode: Four Heads Synchronized Recognition

Service motor: import servo motor

Introduction

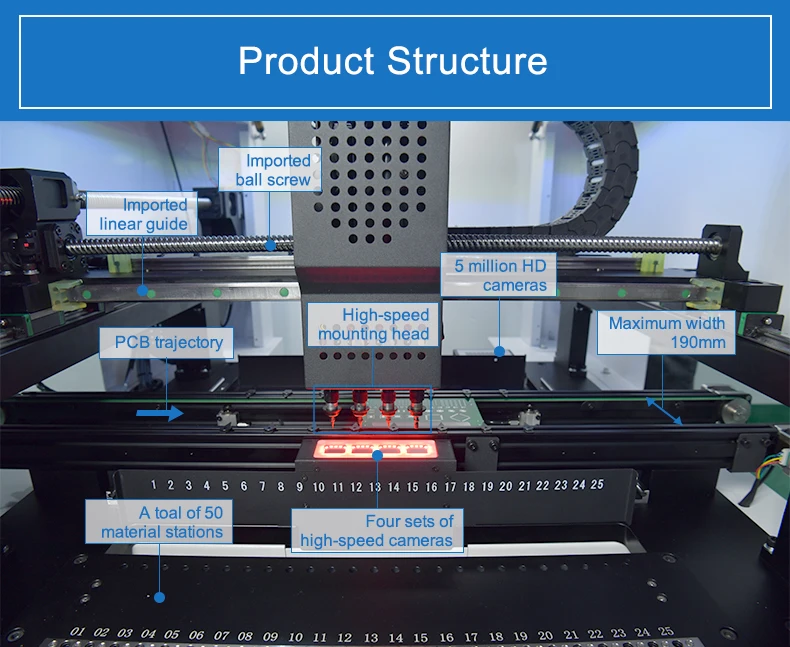

The machine SMT550 with the ball screw and servo motor which is more stable and more accurate than the step motor.

Feature

1.Import servo motor.

2.Straight guide rail.

3.Screw Guide.

4.4 Heads+50 feeders+6 cameras.

Part list

1.Pick and place machine:1Set 2.IC fixed support:4Set(four M5*8,four M5*16)

3.JUKI nozzle:12Pcs (502*2,503*3,504*4,505*2,506*1)

4.Calibration suction nozzle:4Pcs

5.Power wire:1Pcs

6.Fixed foot:4Pcs(Diameter 20mm)

7.The keyboard and mouse:1Set

8.Nozzle calibration inkpad:1Box

9.lubricant:1Pcs

10.Chassis key:1Pcs

11.PC:1Set

12.17 inch liquid crystal display:1Set

The SMT550 software was developed by ourselves. The software is available in English. And our software will be updated, as soon as there is an update, the salesman will send new software to your mailbox.

The SMT550 machine has one year warranty, lifetime maintenance. We have a professional after-sales team. As long as there is a problem with the machine within one year after purchase, we will repair it for free. If there is a need to replace the accessories, we will send them to your hands for free.(Generally we use TNT/DHL. 3-5 business days to your hands).

|

Maximum circuit board area

|

400*200 mm

|

|

Number of mounting heads

|

4

|

|

Maximum movement range of Z axis

|

20 mm

|

|

Maximum mounting rate

|

9,500 PCS/hour

|

|

Average mounting rate

|

8,000 PCS/hour

|

|

Positioning accuracy

|

0.01 mm

|

|

Buffering range of suction nozzle

|

4.5 mm

|

|

Power supply

|

220V/110V, 50 Hz

|

|

Compressed air

|

0.6-0.7 Mpa

|

|

Average power

|

400 W

|

|

Recognition Mode

|

Four Heads Synchronized Recognition

|

|

Number of cameras

|

a Mark camera, four high-speed cameras, a high-definition camera

|

|

Product weight

|

210KG

|

|

PCB access mode

|

automatic Left-in and right-out access, supporting left-right device connection function

|

|

Quantity of trays

|

Up to 48 non-feeder feeding components are supported, each of which can specify its coordinates within the mounting range

|

|

Complex speed to mount resistance and Chip

|

6000/h

|

|

Mounting accuracy range

|

0201-40*40mm,Pin spacing 0.3mm

|

|

Chip(Matching which support electric feeder can mount the 0402,0201)

|

|

|

Quantity of feeders

|

50 PCS

|

|

Service motor

|

Panasonic servo motor

|

|

Guide rail

|

Taiwan TBI Linear Guide rail

|

|

Driving mode

|

Taiwan TBI ball screw

|

|

Nozzle Vacuum Source

|

Japan CKD High Speed On-off Vacuum Generator with Vacuum Damage

|

|

Minimum air capacity of pump

|

80-120 L/min, volume more than 60 L

|

|

Gas quality requirements

|

oil-water separation device, dust filter device, air pressure stabilization device

|

|

Dimension

|

900×1140×900mm

|

Share